Item NO.:

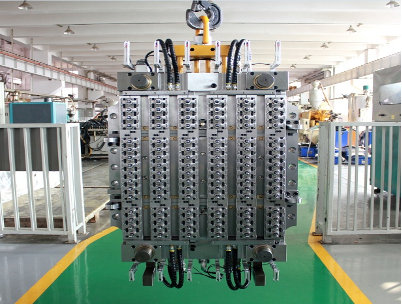

6cavPET preform molds are an essential component in the manufacturing of PET preforms, which serve as the building blocks for high-quality plastic bottles. Renowned suppliers in the industry offer a wide range of PET preform molds, incorporating advanced technology, superior design, and precise engineering. These molds are designed to meet the stringent requirements of the packaging industry, delivering exceptional performance and ensuring consistent, reliable results.

Through years of expertise and innovation, Huayan has established itself as leader in the PET preform mold market. Huayan dedicate to excellence, commitment to customer satisfaction, and continuous research and development have positioned them at the forefront of the industry.

|

(Mold Cav Qty) |

Neck Size) |

Application |

|

18 cav |

48mm, 38mm,30/25,20/25, PCO1881, PCO1810 |

Water, Juice, CSD, Daily chemical products, edible oil, medicine |

|

24 cav |

48mm,38mm,30/25,29/25, PCO1881, PCO1810 |

Water, Juice, CSD, Daily chemical, products, edible oil, medicine |

|

32 cav |

48mm,38mm,30/25,29/25, PCO1881, PCO1810 |

Water, Juice, CSD, Daily chemical products, edible oil, medicine |

|

48 cav |

48mm,38mm,30/25,29/25, PCO1881, PCO1810 |

Water, Juice, CSD, Daily chemical products, edible oil, medicine |

|

56 cav |

48mm, 38mm, 30/25, 29/25, PCO1881, PCO1810 |

Water, Juice, CSD, Daily chemical products, edible oil, medicine |

|

72 cav |

38mm, 30/25,29/25, PCO1881, PCO1810 |

Water, Juice, CSD, Daily chemical products, medicine |

|

96 cav |

38mm, 30/25, 29/25, PCO1881, PCO1810 |

Water, Juice, CSD, Daily chemical products, medicine |

|

112 cav |

30/25, 29/25, PCO1881, PCO1810 |

Water, Juice, CSD, Daily chemical products, edible oil, medicine |

|

128 cav |

30/25, 29/25, PCO1881, PCO1810 |

Water, Juice, CSD, Daily chemical products, edible oil, medicine |

|

144 cav |

30/25, 29/25, PCO1881, PCO1810 |

Water, Juice, CSD, Daily chemical products, edible oil, medicine |

|

176 cav |

30/25, 29/25, PCO1881, PCO1810 |

Water, Juice, CSD, Daily chemical products, edible oil, medicine |

R&D for Injection molds

|

|

We have a professional machinery and research and development team, with high efficiency and stability.

Based on customer's requirements, we can develop and design the bottle embryos, bottle samples and caps, and provide full technical support!It is the practical training and practice base of many universities in China!

Introduction to the mold production environment

|

|

1. High quality molds, need standard environment to produce. Huayan has the stable-temperature environment condition for precise processing workshop to produce.

2. Standard stable-temperature workshop ensure the good working condition for the processing equipment, and guarantee the precision of the equipment.

3. Comfortable and large working environment, could provide good working condition for the technicians, and could support excellent technical experts for the precise molds manufacturing.

Introduction of mold processing equipment

According to the production demand of large-cavity molds, combined with the higher quality of the market, in recent years, Huayan has made great efforts to purchase and update processing equipment, such as CNC grinding machines, five-axis CNC machine tools, engraving machines, etc.

Japan, Europe and the United States and other precision processing equipment has been purchased and replaced the previous generation of machine tools, the key position of the mold, grinding technology instead of the previous generation of turning technology, part accuracy has a qualitative leap, according to the requirements of the drawing, can achieve 0.002 precision requirements.

Introduction to mold manufacturing quality

While upgrading the mold manufacturing environment and updating the machine tools and equipment, Huayan also follows up the inspection and verification means at the same time

The 3-coordinate inspection equipment from Zeiss of Germany was put into use at the same time as the construction of the constant temperature workshop.

Mold manufacturing, to achieve quality controlled and traceable

Mold Design Scheme and Process Optimization

1. The main component is diamond-like, which does not contain metal components, ensuring safety.

2. Friction coefficient is less than 0.1, good self-lubrication.

3. Strong corrosion resistance. 4.

4. Keep the same size after coating treatment, thickness: about 2-3um.

5. The surface of the coating is very fine and can keep the original finish of the workpiece.

6. Abrasion resistance: 5-50 times longer life than uncoated. Mould life up to 8 million open and close.

Hot runner optimization

Benefits:

1. mold thermal balance, glue channel balance effect is very excellent;

2. No hot runner dust will be generated

3. The hot runner adopts elastic contact sealing scheme.

No matter what state can be close to the sealing surface of the hot runner plate.

Ensure long-term use will not leak glue;

4. Hot runner adopts inlay structure, good sealing effect, stable temperatureIntroduction.